IMPORTANT UPDATE:

Rubber Industries is designated as an essential manufacturer due to our Medical and Department of Defense manufacturing.

We continue to operate all aspects of our tooling and manufacturing 24x7x365

Butyl Rubber Custom Molding

- First, some background on Rubber Industries, Inc:

- Celebrating 50 years under one ownership. We've invested millions in our USA plant in these last four years.

- Consistency in ownership leads to consistency in quality, service, and pricing.

- We are the fastest in the industry from CAD to tooling to production. For example: we've made production tooling and shipped 10,000+ custom silicone parts in one week. We designed and programmed, cut steel into a 19" x 23" custom multi-cavity tool, and custom molded all in 7 days.

- Rubber Injection, Transfer, Compression Custom Molding

- LSR (Liquid Silicone Rubber) custom molding

- Custom Silicone Molding Injection, Transfer, Compression

- Overmolding onto many materials including glass filled nylon for demanding applications

- Rubber to Metal Bonding and Silicone Overmolding (this is one third of our business, we are the experts in this segment)

- Asian partner for custom molded rubber, silicone, LSR

- Serving all segments of silicone molding and rubber molding:

- Consumer

- Medical

- Automotive

- Industrial

- Automotive

- Medical

- Consumer

- Multiple large injection presses (up to 15 pound shot), transfer presses, compression presses, silicone molding presses, and multiple precise LSR presses

Butyl rubber is used in many applications, typically can be an excellent selection for medical applications like stoppers, etc. and is also very good for shock absorption for industrial applications. It also has good resistance to hydraulic fluids, as well as resistance to the environment and low gas permeability. Items include; heat, ozone, chemical, abrasion, tearing, weather, etc.

Butyl also can have excellent electrical insulation performance when the compound is engineered correctly. In general, there are some petroleum oils and petroleum-based fluids that butyl is not recommended for use. You can count on Rubber Industries, Inc to help with your choice of the proper approach of material selection for your custom rubber molded project, whether it is for injection rubber molding, transfer rubber molding, or compression rubber molding.

Butyl also can have excellent electrical insulation performance when the compound is engineered correctly. In general, there are some petroleum oils and petroleum-based fluids that butyl is not recommended for use. You can count on Rubber Industries, Inc to help with your choice of the proper approach of material selection for your custom rubber molded project, whether it is for injection rubber molding, transfer rubber molding, or compression rubber molding.

|

|

What Is Butyl Rubber and Why Is It So Useful?

Rubber is a fascinating substance. Many people are aware that the source of rubber was the rubber tree, which contains a milky fluid called latex, the chief source of natural rubber. Few people realize that there are as many as 200 plants that exude latex when you cut them, though most rubbers came from the Hevea brasiliensis, the technical name for the rubber trees located in South America’s rain-forests.

How was Butyl Rubber involved in the Industrial Revolution?

The process of curing this latex substance to make rubber dates back to prehistoric times. In the mid-19th century, Charles Goodyear combined sulfur, latex, and high heat to create a product superior to anything previously imagined, well-suited for the automobile industry that would eventually emerge a generation later. This process, called Vulcanization (after the mythological god of fire, volcanoes, metalworking and the forge), became the basis for the tire industry. In modern times, however, through organic chemistry synthetic rubbers were developed with improved properties with even broader applications for the industrial age.

Ways how is synthetic rubber used:

One of the transforming developments of the twentieth century has been the ability to use chemical processes to create synthetic products that improve the characteristics of items found in nature. As a result, chemists have been able to combine natural materials into a nearly limitless array of plastics, films, fabrics, and fluids. By understanding the geometry of organic compounds, chemists could create customized molecular designs to achieve preconceived objectives.

How is Butyl Rubber Different from Natural Rubber?

One of these designs has come to be a synthetic substance known as butyl rubber, a copolymer consisting of isobutylene and isoprene. Butyl rubber has many advantages over natural rubber. It's more flexible, is resistant to ozone, is air tights and gas impermeable, and a good vibration damper. It not only offers superior resistance to abrasion than natural rubber, but it is also more resistant to heat and the effects of aging.

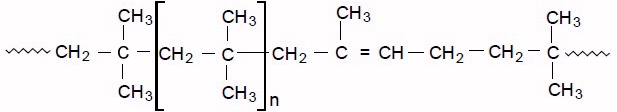

What is the formula for Butyl Rubber?

Butyl rubber has superior impermeability, and the long polyisobutylene parts of its polymer chains give it sufficient flex characteristics.

The formula for PIB is: –(–CH2–C(CH3)2–)n–

The butyl rubber formula:

It is made from the monomer isobutylene (CH2=C(CH3)2) only by cationic addition polymerization.

The Benefits of Butyl Rubber

The applications are numerous and still being discovered. The first application of butyl rubber was for tire inner tubes, a usage that has continued right up to the present. Butyl rubber is used for shock mounts, tubeless tire liners, inner tubes, as a sealant for rubber roof repair, tank liners, and butyl O-rings. You may be familiar with their use as stoppers for glass bottles, medicine bottles, and pharmaceuticals. It is also used in sealants and adhesives, as well as hoses and a variety of mechanical goods. Butyl gives caulks and sealants their added flexibility. It’s also used in fiber optics, paper and pulp, personal care products, coffee cups, and agricultural chemicals.

Have you ever wondered what is inside that basketball, football or rugby ball? Yes, it’s a butyl bladder that serves as a durable, airtight inner compartment.

Moreover, yes, it’s even used in chewing gum. Today’s chewing gum uses food-grade rubber as its base, giving it not only elasticity but also a sticky quality. It can even be recycled to recover its polyisobutylene content.

How was Butyl Rubber involved in the Industrial Revolution?

The process of curing this latex substance to make rubber dates back to prehistoric times. In the mid-19th century, Charles Goodyear combined sulfur, latex, and high heat to create a product superior to anything previously imagined, well-suited for the automobile industry that would eventually emerge a generation later. This process, called Vulcanization (after the mythological god of fire, volcanoes, metalworking and the forge), became the basis for the tire industry. In modern times, however, through organic chemistry synthetic rubbers were developed with improved properties with even broader applications for the industrial age.

Ways how is synthetic rubber used:

One of the transforming developments of the twentieth century has been the ability to use chemical processes to create synthetic products that improve the characteristics of items found in nature. As a result, chemists have been able to combine natural materials into a nearly limitless array of plastics, films, fabrics, and fluids. By understanding the geometry of organic compounds, chemists could create customized molecular designs to achieve preconceived objectives.

How is Butyl Rubber Different from Natural Rubber?

One of these designs has come to be a synthetic substance known as butyl rubber, a copolymer consisting of isobutylene and isoprene. Butyl rubber has many advantages over natural rubber. It's more flexible, is resistant to ozone, is air tights and gas impermeable, and a good vibration damper. It not only offers superior resistance to abrasion than natural rubber, but it is also more resistant to heat and the effects of aging.

What is the formula for Butyl Rubber?

Butyl rubber has superior impermeability, and the long polyisobutylene parts of its polymer chains give it sufficient flex characteristics.

The formula for PIB is: –(–CH2–C(CH3)2–)n–

The butyl rubber formula:

It is made from the monomer isobutylene (CH2=C(CH3)2) only by cationic addition polymerization.

The Benefits of Butyl Rubber

The applications are numerous and still being discovered. The first application of butyl rubber was for tire inner tubes, a usage that has continued right up to the present. Butyl rubber is used for shock mounts, tubeless tire liners, inner tubes, as a sealant for rubber roof repair, tank liners, and butyl O-rings. You may be familiar with their use as stoppers for glass bottles, medicine bottles, and pharmaceuticals. It is also used in sealants and adhesives, as well as hoses and a variety of mechanical goods. Butyl gives caulks and sealants their added flexibility. It’s also used in fiber optics, paper and pulp, personal care products, coffee cups, and agricultural chemicals.

Have you ever wondered what is inside that basketball, football or rugby ball? Yes, it’s a butyl bladder that serves as a durable, airtight inner compartment.

Moreover, yes, it’s even used in chewing gum. Today’s chewing gum uses food-grade rubber as its base, giving it not only elasticity but also a sticky quality. It can even be recycled to recover its polyisobutylene content.

Rubber Industries, Inc. is a custom molded rubber manufacturer please contact us for the fastest turn around times and competitive quotes from either our USA manufacturing plant of our high volume butyl rubber plant located in China.

For custom molded and overmolded applications, butyl can be the best choice of material. Well known and versatile, this synthetic compound can be used to make products from every category that can stand up to many kinds of potential damage from chemicals or weather exposure. This makes it a solid choice for any components that will be used primarily outdoors, and also in medical segments for items like stoppers.

First invented in the late 1930s, butyl was one of the first synthetic elastomers to be created. In-house scientists at Exxon had to experiment with the composition of the material to get a stable synthetic elastomer they could use for industrial applications and parts, like on the inside of automotive tires. As a bonus, they also created a form of rubber that can’t be permeated by oxygen molecules, making it perfect material to use in gaskets, stoppers, seals, and o-rings for automotive and aviation parts. Butyl rubber is still one of the best materials on the market for creating a secure seal that keeps anything you need to form a barrier from the environment, or a part that has to stay intact over years of use. It's also popular with medical professionals who want to protect against contamination and the spread of germs. Used in weatherproofing application and to protect the home against damages, it can be present in many areas you have never realized.

The versatility and popularity of this elastomer means that it has been used in many different ways over the years to great success. Forms of this chemical compound are used in the production of many industrial and consumer goods you might not expect, including:

O-rings

Sealant

Caulk

Diaphragms

Bellows

Gaskets

Medical supplies

Adhesives

Engine components

To create your own custom molded products like seals, bellows, stoppers, diaphragms or other parts you need as part of your industrial rubber or medical parts, all you need is a skilled manufacturing partner who understands your specifications.

At Rubber Industries, we can partner with you to help you find the right manufacturing approach, i.e., injection, transfer, or compression molding, and materials for your product and budget. Our skilled manufacturing team can handle custom tooling, overmolded products, and custom molded applications to help you get a strong, durable end product made to the most exacting tolerances and dimensions, making sure you will be satisfied with your end product. With our Minneapolis office in the United States and partnerships in Asia, we can handle the manufacturing of very high volume orders in a short time frame. Our production line never shuts down, and our turnaround time is the fastest in the industry. Though we work fast, all of our manufacturing is of high quality, designed to produce components you can rely on and be assured of the quality needed for your application. Our expertise with making custom tooling and custom molded rubber production means that we can complete your order on time, no matter how complex it is, and have it shipped directly to you by your preferred deadline. Contact us to get the process started today and find out exactly how we can help you.

First invented in the late 1930s, butyl was one of the first synthetic elastomers to be created. In-house scientists at Exxon had to experiment with the composition of the material to get a stable synthetic elastomer they could use for industrial applications and parts, like on the inside of automotive tires. As a bonus, they also created a form of rubber that can’t be permeated by oxygen molecules, making it perfect material to use in gaskets, stoppers, seals, and o-rings for automotive and aviation parts. Butyl rubber is still one of the best materials on the market for creating a secure seal that keeps anything you need to form a barrier from the environment, or a part that has to stay intact over years of use. It's also popular with medical professionals who want to protect against contamination and the spread of germs. Used in weatherproofing application and to protect the home against damages, it can be present in many areas you have never realized.

The versatility and popularity of this elastomer means that it has been used in many different ways over the years to great success. Forms of this chemical compound are used in the production of many industrial and consumer goods you might not expect, including:

O-rings

Sealant

Caulk

Diaphragms

Bellows

Gaskets

Medical supplies

Adhesives

Engine components

To create your own custom molded products like seals, bellows, stoppers, diaphragms or other parts you need as part of your industrial rubber or medical parts, all you need is a skilled manufacturing partner who understands your specifications.

At Rubber Industries, we can partner with you to help you find the right manufacturing approach, i.e., injection, transfer, or compression molding, and materials for your product and budget. Our skilled manufacturing team can handle custom tooling, overmolded products, and custom molded applications to help you get a strong, durable end product made to the most exacting tolerances and dimensions, making sure you will be satisfied with your end product. With our Minneapolis office in the United States and partnerships in Asia, we can handle the manufacturing of very high volume orders in a short time frame. Our production line never shuts down, and our turnaround time is the fastest in the industry. Though we work fast, all of our manufacturing is of high quality, designed to produce components you can rely on and be assured of the quality needed for your application. Our expertise with making custom tooling and custom molded rubber production means that we can complete your order on time, no matter how complex it is, and have it shipped directly to you by your preferred deadline. Contact us to get the process started today and find out exactly how we can help you.

At Rubber Industries, we have spent over 50 years perfecting the art of providing people like you with the high-quality tools and items they need to complete every important project with ease. We use a wide variety of materials in order to ensure you have access to the parts you need the most. The information below will talk about butyl rubber in more detail. It will also highlight some of the advantages that this unique material has to offer.

What is Butyl Rubber?

Butyl rubber is a manmade polymer that is created by copolymerizing a material known as isobutylene with small amounts of another material known as isoprene. Butyl rubber is often used in automobile tires and other robust applications that demand a lot of wear and tear. Since it also boasts great shock absorption, butyl rubber is also frequently put to use in high-grade medical equipment.

Advantages of Butyl Rubber

Butyl rubber can offer many different advantages that may suit project requirements in several different specialties. Consider the following list of advantages provided by this unique and diverse material:

* Chemical Inertness

Butyl rubber remains stable in many different conditions, allowing it to be a very versatile material in many fields. It does not react with different chemicals, making it a great choice for automotive and medical industries.

* Gas Impermeability

Butyl rubber is also highly impermeable by various gases. This is yet another reason why it is frequently used in the automotive industry where exposure to various gases is prevalent.

* Superior Weatherability

Butyl rubber has the ability to perform exceptionally well in many extreme weather conditions. Whether exceptionally high or extremely low temperatures are the norm, butyl rubber is often able to outperform other materials in these same weather conditions.

* Resistance to Oils

Since it is not permeable, butyl rubber is a great material to use in situations where there will be a lot of exposure to grease, oil, and other common slick substances. This makes butyl rubber a preferred choice for many in medical and automotive industries where keeping machinery properly lubricated is essential to maintaining its effectiveness and longevity.

* Abrasion Resistance

Many situations require that materials become exposed to harsh objects that can wear them down over time. In the case of automobile tires, it is no surprise that these objects are exposed to many abrasive materials and circumstances. Butyl rubber is thick and tough, making it highly resistant to the damage that can come about from abrasive materials and situations.

What is Butyl Rubber?

Butyl rubber is a manmade polymer that is created by copolymerizing a material known as isobutylene with small amounts of another material known as isoprene. Butyl rubber is often used in automobile tires and other robust applications that demand a lot of wear and tear. Since it also boasts great shock absorption, butyl rubber is also frequently put to use in high-grade medical equipment.

Advantages of Butyl Rubber

Butyl rubber can offer many different advantages that may suit project requirements in several different specialties. Consider the following list of advantages provided by this unique and diverse material:

* Chemical Inertness

Butyl rubber remains stable in many different conditions, allowing it to be a very versatile material in many fields. It does not react with different chemicals, making it a great choice for automotive and medical industries.

* Gas Impermeability

Butyl rubber is also highly impermeable by various gases. This is yet another reason why it is frequently used in the automotive industry where exposure to various gases is prevalent.

* Superior Weatherability

Butyl rubber has the ability to perform exceptionally well in many extreme weather conditions. Whether exceptionally high or extremely low temperatures are the norm, butyl rubber is often able to outperform other materials in these same weather conditions.

* Resistance to Oils

Since it is not permeable, butyl rubber is a great material to use in situations where there will be a lot of exposure to grease, oil, and other common slick substances. This makes butyl rubber a preferred choice for many in medical and automotive industries where keeping machinery properly lubricated is essential to maintaining its effectiveness and longevity.

* Abrasion Resistance

Many situations require that materials become exposed to harsh objects that can wear them down over time. In the case of automobile tires, it is no surprise that these objects are exposed to many abrasive materials and circumstances. Butyl rubber is thick and tough, making it highly resistant to the damage that can come about from abrasive materials and situations.

Common Uses for Butyl Rubber

As a whole, the rubber industry grew to enormous popularity with the invention of the bicycle prior to the 1900s. The need for an exceptional and durable material of this nature was only further solidified with the invention of the automobile. Regular rubber materials remain in high demand today for many different household items. However, butyl rubber comes into play when the needs of the situation require exceptional durability, weatherability, and long-lasting effectiveness. Since butyl rubber meets all these criteria and more, it is highly sought after in medical, factory, automotive, and even military settings. Tires, hoses, sealants, and heavy machinery of all types rely on the use of items made from butyl rubber.

At Rubber Industries, we understand that time is precious. Wasting time waiting for the right products to become available can be a huge detriment to your productivity and your overall bottom line. Our production team is equipped to provide you with the fastest turnover in the industry by operating one of the largest manufacturing facilities in the US. We also combine forces with several overseas facilities to provide you with continual access to parts and products of the highest caliber.

Furthermore, we can customize each product to meet the individual demands of your business requirements. If you would like to receive a custom quote on an upcoming project, please contact our customer service department for assistance. We would love to help you make a huge success of your next project.

As a whole, the rubber industry grew to enormous popularity with the invention of the bicycle prior to the 1900s. The need for an exceptional and durable material of this nature was only further solidified with the invention of the automobile. Regular rubber materials remain in high demand today for many different household items. However, butyl rubber comes into play when the needs of the situation require exceptional durability, weatherability, and long-lasting effectiveness. Since butyl rubber meets all these criteria and more, it is highly sought after in medical, factory, automotive, and even military settings. Tires, hoses, sealants, and heavy machinery of all types rely on the use of items made from butyl rubber.

At Rubber Industries, we understand that time is precious. Wasting time waiting for the right products to become available can be a huge detriment to your productivity and your overall bottom line. Our production team is equipped to provide you with the fastest turnover in the industry by operating one of the largest manufacturing facilities in the US. We also combine forces with several overseas facilities to provide you with continual access to parts and products of the highest caliber.

Furthermore, we can customize each product to meet the individual demands of your business requirements. If you would like to receive a custom quote on an upcoming project, please contact our customer service department for assistance. We would love to help you make a huge success of your next project.