IMPORTANT UPDATE:

Rubber Industries is designated as an essential manufacturer due to our Medical and Department of Defense manufacturing.

We continue to operate all aspects of our tooling and manufacturing 24x7x365

Custom Die-Cut Rubber Parts

Die-Cut Rubber What Are Die Cut Rubber Parts?

Die-cut rubber parts are a little different from the other rubber products we sell. They're not melted down, jammed into a press, and forced into a mold like a lot of our other products are. When we use die-cut rubber, we use custom cutting dies to essentially stamp out different parts very quickly.

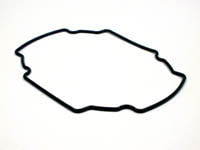

We use this process to make a lot of our gaskets. Due to how simple gaskets are, we can use gasket cutting dies to complete entire orders in record time.

Die-cut rubber parts are a little different from the other rubber products we sell. They're not melted down, jammed into a press, and forced into a mold like a lot of our other products are. When we use die-cut rubber, we use custom cutting dies to essentially stamp out different parts very quickly.

We use this process to make a lot of our gaskets. Due to how simple gaskets are, we can use gasket cutting dies to complete entire orders in record time.

Custom Die-Cut Rubber Gasket

Custom Die-Cut Rubber Gasket

Why are die-cut rubber parts used?

It's a very fast process. It doesn't require a lot of the complicated steps involved in injection-molding. It's relatively inexpensive when compared to other manufacturing methods. How We Make Die-Cut Rubber Parts

Making custom cut rubber isn't exactly a complicated process. We didn't invent it, but we did invest in the equipment necessary to outpace our competitors regardless of your order size. Here's how our die-cut rubber parts are made.

It's a very fast process. It doesn't require a lot of the complicated steps involved in injection-molding. It's relatively inexpensive when compared to other manufacturing methods. How We Make Die-Cut Rubber Parts

Making custom cut rubber isn't exactly a complicated process. We didn't invent it, but we did invest in the equipment necessary to outpace our competitors regardless of your order size. Here's how our die-cut rubber parts are made.

How is a standard Die Cut gasket made?

First, we have to know exactly what type of gasket you need. We need the dimensions of your desired product, and we need to know what it will be used for to determine what material will suit the part the best.

After you've given us the dimensions for your product, or after you've worked with one of our highly qualified engineers to design a blueprint, we can begin our prototyping phase. All of our rubber products are made from scratch. So, we have to make a prototype before we can start production. Luckily, we're so fast that it only takes us twenty-four hours to make a fully functional prototype.

Finally, we can begin producing your order. Since the die-cutting process requires pre-made rubber sheets, we have to choose the proper material from our expansive stock of more than 2000 rubber formulas.

Once we have a material picked out, we have to set our presses up with the exact measurements necessary to cut your parts properly. If our engineers are even a fraction of an inch off the mark, the products will come out wrong. So, we only hire the best staff possible to ensure that our products meet your expectations.

After the machines are set up, the rest of the process is fairly automated. The rubber material sheets are fed into a press, and the press uses our custom-made gasket cutting dies to cut out several parts at a time. In a lot of ways, it's a lot like making homemade cookies, but it's on a much larger scale. Instead of dough, we use rubber, and our cookie cutters are metal dies that cut through thick rubber as if it's made out of butter.

There aren't any other steps after all of the parts are cut out. Since the rubber is never heated or deformed, there's no need to wait for it to cure or cool down. The parts are immediately ready to be shipped to their final destination.

Our Service

At Rubber Industries, we strive to stand out from our competition by offering the fastest and highest quality service possible. We know that your company relies on our parts for various reasons, and we have done our best to perfect our manufacturing processes to get your parts to you faster and more reliably.

Here are a few ways that we outperform our competition.

24/7 Performance

We don't shut our services down for weekends and holidays. We don't even shutdown at night. We keep our machines running every hour of the day and every day of the year. That makes it so you know you can always contact us, and your order is never put on the back burner.

No Hidden Fees

If you've worked with other rubber manufacturers, you've probably had to deal with hidden engineering fees. Those fees are typically tacked on to pay for the work that the engineers do to create cutting tools and prototypes. That's not the case with us.

When we give you a price quote, that is the amount that you pay. We won't wait until the last minute to tack on engineering fees or anything else.

Everything Is Custom

We don't have a list of pre-made parts for you to choose from. We make everything specifically for your individual project. Every time a customer comes to us, we start our entire process over from scratch. We cut new tools, make new prototypes, and build new molds. We do all of that to make sure that our parts match your project.

What We Have To Offer

At Rubber Industries, we've had 50 years to learn how to properly perform every type of rubber manufacturing process. We don't just offer custom cut rubber. We offer injection-molded rubber parts, transfer pressed parts, and many other types of parts.

Here's a complete list of our most popular offerings.

Custom tooling Injection molding Transfer press Die-cut rubber Liquid silicone rubber Completely custom parts 2000 rubber formulas to choose from Unparalleled speed and reliability 24-hour prototyping Custom colors Food-safe products Medical-grade products Contact Us

At Rubber Industries, we've had 50 years to learn how to properly perform every type of rubber manufacturing process. We don't just offer custom cut rubber. We offer injection-molded rubber parts, transfer pressed parts, and many other types of parts.

Here's a complete list of our most popular offerings.

Custom tooling Injection molding Transfer press Die-cut rubber Liquid silicone rubber Completely custom parts 2000 rubber formulas to choose from Unparalleled speed and reliability 24-hour prototyping Custom colors Food-safe products Medical-grade products Contact Us

For more information about die cutting here is a link to Wikipedia