Phone: 952-445-1320

IMPORTANT UPDATE:

Rubber Industries is designated as an essential manufacturer due to our Medical and Department of Defense manufacturing.

We continue to operate all aspects of our tooling and manufacturing 24x7x365

Custom Silicone Molding and Liquid Silicone Rubber (LSR) Molding

Phone: 952-445-1320

At Rubber Industries, we mold custom silicone parts to help meet your project performance needs. We manufacture millions of silicone parts, including all shapes and sizes of silicone products and overmolded silicone parts.

We have cleanroom molding in both the USA and China (ISO 13485).

Silicone molded parts provide many benefits, including a wide temperature operating range, UV and ozone resistance, good compression set, as well as customizing to your specific project needs.

Rubber Industries manufactures tens of millions of silicone parts annually and is a leading supplier to a distinguished list of companies.

Custom silicone parts provide additional benefits to you by matching the custom part to best meet your project needs.

We have cleanroom molding in both the USA and China (ISO 13485).

Silicone molded parts provide many benefits, including a wide temperature operating range, UV and ozone resistance, good compression set, as well as customizing to your specific project needs.

Rubber Industries manufactures tens of millions of silicone parts annually and is a leading supplier to a distinguished list of companies.

Custom silicone parts provide additional benefits to you by matching the custom part to best meet your project needs.

Just a few examples of the world's top brands that trust us with their most critical custom parts ... !

- You can have your silicone parts in 1 to 10 days, from your CAD to building a real, steel mold, and shipping your actual prototype and production parts.

- Don't waste your time and money on temporary aluminum tooling or non-functioning parts! Hit your deadlines with real parts from steel tooling that doesn't have a limited life or durability like aluminum.

- We are the only company that can take you from actual working proto parts to millions of production parts all under one roof on our 5 acre campus. Plus, we have invested with capacity in Asia, so we provide incredible value from startup to long term production.

- Rubber Industries provide the fastest prototype and production capabilities for your project. We are the fastest in the industry at first quality, actual custom silicone parts!

- 50 years of providing the best service, best quality, all under one ownership.

- Consistency of ownership leads to consistency in service, quality, and pricing!

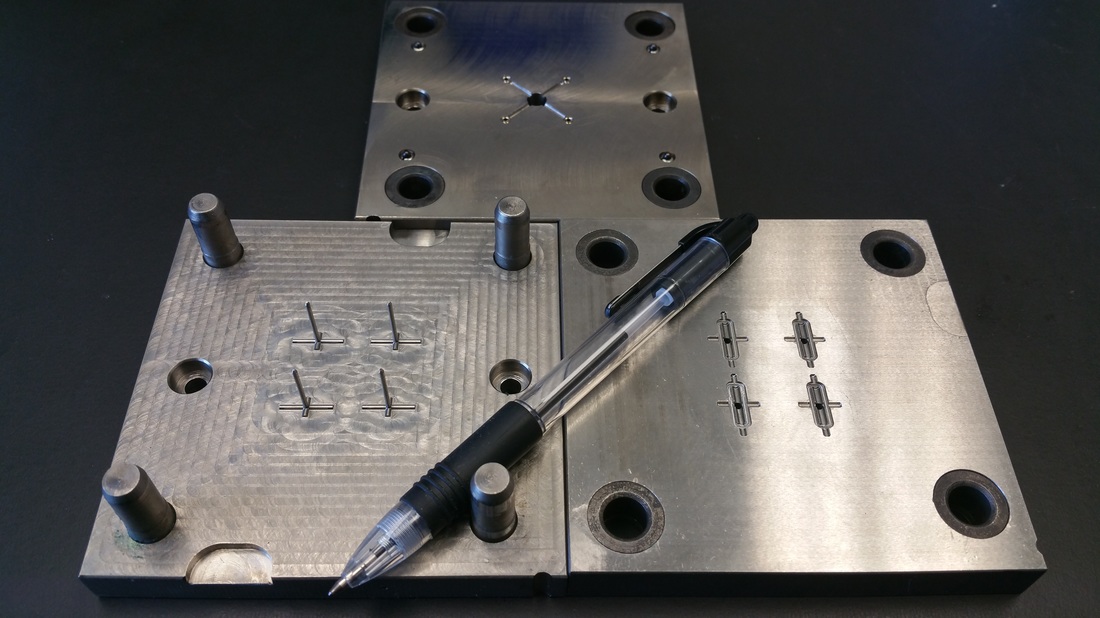

Custom Silicone Molding Pictures

|

|

We are the fastest at manufacturing custom silicone parts, including silicone overmolded parts with our on-site tooling and molding. We can manufacture your custom silicone parts in days, not weeks.

We mold Liquid Silicone Rubber (LSR) parts in our cleanrooms with our Liquid Injection Molding (LIM) process and provide the fastest service of prototyping and production of silicone parts.

We manufacture with peroxide cured HCR silicone for silicone gaskets with the manufacturing processes of silicone injection, silicone transfer molding, and compression molding of silicone.

We mold Liquid Silicone Rubber (LSR) parts in our cleanrooms with our Liquid Injection Molding (LIM) process and provide the fastest service of prototyping and production of silicone parts.

We manufacture with peroxide cured HCR silicone for silicone gaskets with the manufacturing processes of silicone injection, silicone transfer molding, and compression molding of silicone.

At Rubber Industries, we do all types of silicone molding, including:

- LSR (Liquid Silicone Rubber)

- Injection Molding

- Liquid Injection Molding (LIM) of Liquid Silicone Rubber

- Transfer Molding

- Compression Molding

- Medical

- Automotive

- Industrial

- Consumer

- Defense

Custom Silicone Molding Picture

Custom Silicone Molded Parts

We'll help choose the best silicone molding process for you based on the part performance properties needed, quantities, size of the part, and cost. We aren't limited in how we approach your project because we have all silicone molding technologies in house. We match the custom silicone molding process to best match the custom molded part you are desiring to have molded.