Phone: 952-445-1320

IMPORTANT UPDATE:

Rubber Industries is designated as an essential manufacturer due to our Medical and Department of Defense manufacturing.

We continue to operate all aspects of our tooling and manufacturing 24x7x365

Silicone Injection Molding and LSR Molding

Phone: 952-445-1320

What is Injection Molding of Silicone?

Silicone injection molding is a manufacturing process developed for the molding of plastics, while injection molding of silicone rubber began in the 60's and 70's. Injection molding successfully alters the process by heating the silicone rubber and placing it under significantly more pressure per square inch of cavity surface in the custom silicone molding process. This is different from the plastic injection molding process. Through various innovations, injection molding has become one of the most efficient ways to create custom silicone molded products.

First, a little background on Rubber Industries, Inc

- Celebrating 50 years so you can count on us for your project now and into the future.

- We've invested millions in our USA plant in just these last four years to better serve you.

- Continuity of ownership leads to consistency in quality, service, and pricing.

- We are the fastest in the industry from CAD to tooling to production.

- For example: we've made production tooling and shipped 10,000+ custom silicone parts in one week. We designed and programmed, cut steel into a 19" x 23" custom multi-cavity tool, and custom molded all in 7 days.

Rubber Industries, Inc - Silicone Injection Molding

|

|

Silicone Injection Molding Advantages

The process of injection molding starts with efficient material preparation. To begin, the material is mixed in bulk and then prepared in various ways for injection molding, but it isn't stripped, but rather put in large sizes of up to a few pounds each that are put in a "stuffer" on the injection press.

Advantages:

Advantages:

- Silicone rubber has unique properties and has capabilities that other elastomers don't, but it can be more expensive per pound so the process of silicone injection molding helps reduce the waste of custom molded silicone compared to other processes.

- The complete elimination of pre-forms. The production and need for pre-forms is a labor intensive step that can potentially affect the finished product through variability in pre-form weight and shape.

- Elimination of operator placement of pre-forms. Since pre-forms are eliminated, the need for operators to place the pre-forms in a cavity (compression molding) or pot (transfer molding) is removed.

- Injection screw pre-heats material before forcing it into cavities. This process decreases the viscosity of the material, allowing it to flow more easily into the mold cavities. Pre-heating provides the potential for decreased cure times through more rapid cavity filling due to lower viscosity.

LSR (Liquid Silicone Rubber) Injection Molding

Silicone injection Molding advantages:

Rubber Industries can offer a variety of other silicone and custom molded rubber products through rubber compression molding and rubber transfer molding.

- Reduced cycle time

- Controlled Flash

- Economical process for high volumes of medium to high precision components

- Capable of producing overmolded components

- Minimal material waste

Rubber Industries can offer a variety of other silicone and custom molded rubber products through rubber compression molding and rubber transfer molding.

Video Of Silicone Injection Molding

|

|

Custom Silicone Injection Molding Video

This video is of a custom molded silicone injection process. We (Rubber Industries) built the injection tooling in house. The silicone is a specially developed in house silicone formula to pass high temperature fire ratings in a specialized commercial application. We developed the tooling design, manufacturing process, and special performing silicone material, all on our 5 acre campus in Minneapolis, MN.

Your one stop, from prototype to production including specialized materials to enhance your project requirements. We are the silicone injection experts!

Your one stop, from prototype to production including specialized materials to enhance your project requirements. We are the silicone injection experts!

Who We Are

We make custom molded rubber, silicone molding, LSR molding and custom tooling. We handle the entire process, from prototype to production.

Choose us for your custom molded rubber, LSR, and silicone injection parts.

Reasons to Choose Rubber Industries, Inc. Custom Tooling and Manufacturing Facility

Contact us today to get a price quote or start planning out your project.

Services We Provide to Our Customers

The services we perform include:

•Silicone Injection, transfer, compression and custom molding or rubber elastomers as well, like EPDM, NBR (Nitrile), Neoprene, etc

•LSR custom molding

•Custom silicone molding and overmolding using all the custom molding processes of injection, transfer and compression. We aren't limited to just one or two custom molding processes.... we fit the process to your part and project, not the other way around

•Silicone Over-molding onto many materials including glass filled nylon for demanding applications

We make custom molded rubber, silicone molding, LSR molding and custom tooling. We handle the entire process, from prototype to production.

Choose us for your custom molded rubber, LSR, and silicone injection parts.

- We make tens of millions of customized parts every year.

- Our CNC shop produces hundreds of new tools annually.

- Our custom molded silicone parts are made and developed in the USA.

- Single ownership for more than 50 years.

- We have the industry's fastest and most complete silicone prototyping with silicone production services.

Reasons to Choose Rubber Industries, Inc. Custom Tooling and Manufacturing Facility

- We offer the fastest and most complete prototyping and production services in the industry.

- We have created production tooling and shipped more than 10,000 custom silicone parts to a client in one week. From designing and programming the machinery to cutting the steel into a 19-inch by 23-inch customized multi-cavity tool, the job was finished in just seven days.

- We maintain the fastest prototyping and production services.

- We've invested millions of dollars in our American manufacturing plant.

- Consistent ownership means consistent quality, service and prices.

- We operate 24 x 7 x 365. We manufacture every day of the year so you get more value from your tooling!

Contact us today to get a price quote or start planning out your project.

Services We Provide to Our Customers

- Turn to us for all of your silicone injection needs.

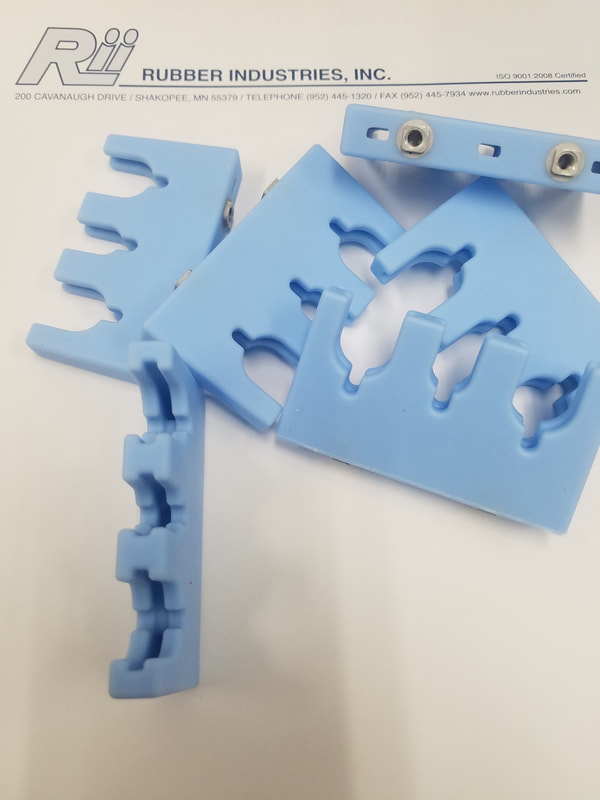

- We also specialize in silicone to metal bonded, silicone to stainless over-molding, and silicone to aluminum overmolding.

- Overmolding is one-third of our business - we are the experts in this space.

- We work with the brands you trust daily trust rubber industries to manufacture their most critical parts.

The services we perform include:

•Silicone Injection, transfer, compression and custom molding or rubber elastomers as well, like EPDM, NBR (Nitrile), Neoprene, etc

•LSR custom molding

•Custom silicone molding and overmolding using all the custom molding processes of injection, transfer and compression. We aren't limited to just one or two custom molding processes.... we fit the process to your part and project, not the other way around

•Silicone Over-molding onto many materials including glass filled nylon for demanding applications

Our Areas of Expertise

It pays to work with industry experts for what you need. When you choose us, you get exactly what you need. We have also earned many industry certifications. Our areas of expertise include:

•Silicone to metal bonded, Silicone to stainless bonded, and silicone overmolded products.

•USA based ITAR & ISO 9001:2015 registered.

•Medical products, which is our larges service segment.

It pays to work with industry experts for what you need. When you choose us, you get exactly what you need. We have also earned many industry certifications. Our areas of expertise include:

•Silicone to metal bonded, Silicone to stainless bonded, and silicone overmolded products.

•USA based ITAR & ISO 9001:2015 registered.

•Medical products, which is our larges service segment.

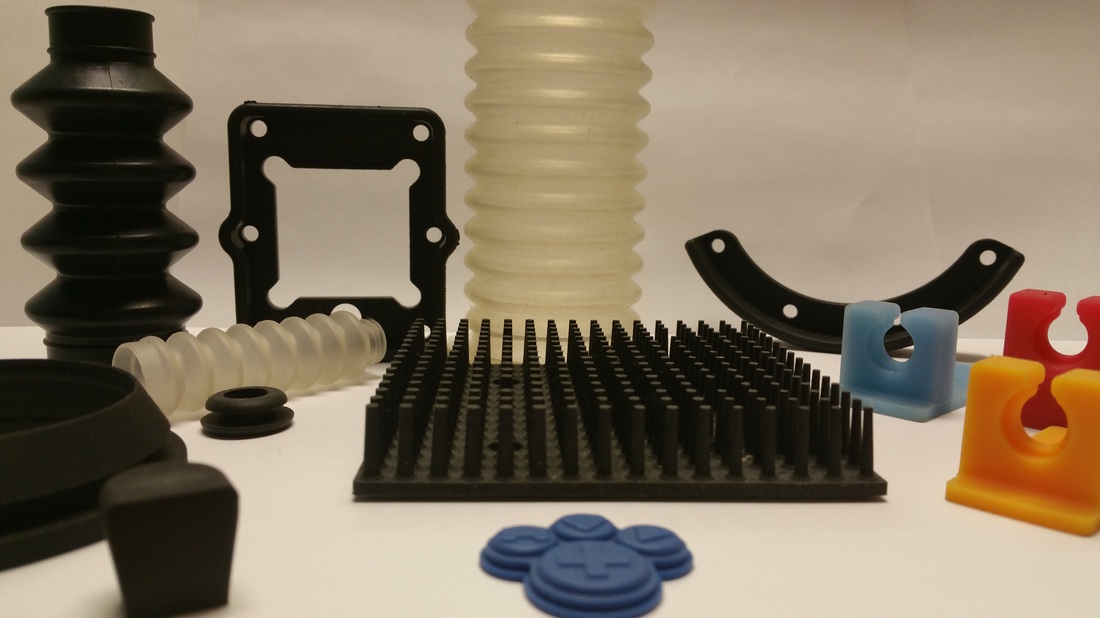

Custom Silicone Molding

Silicone Injection molding is very effective for medium and high volume custom molded silicone parts. Custom silicone parts are used in a variety of applications. Custom silicone gaskets, custom seals, custom handgrips, custom o-rings, and custom silicone molded parts are used in environments of high temperature applications where temperature resistance is key. Silicone is also excellent for resistance of environmental considerations like chemicals, ozone, etc. One other consideration for using silicone is the high quality color reproduction to match your project design.

At Rubber Industries we do custom silicone injection molding using both processes of HCR (High Consistency Rubber or gum stock) and liquid silicone rubber (LSR). Both processes utilize injection molding, but each of the rubber molds are built very differently to accomplish the final part.

We build all the tooling in our tool shop on site for our domestic projects, and we design the tooling specifically for the type of injection process used for both silicone and liquid silicone rubber.

The silicone injection molding process is used with both HCR (gum stock) silicone and also for LSR (liquid silicone rubber). Both of these processes use injection molding technology to increase throughput while minimizing waste. This helps lower per part price.

Silicone prototypes are commonly used to refine the design process (fit/form/function) and it is common for Rubber Industries to make a silicone prototype tool in just a few days including custom silicone parts.

At Rubber Industries we do custom silicone injection molding using both processes of HCR (High Consistency Rubber or gum stock) and liquid silicone rubber (LSR). Both processes utilize injection molding, but each of the rubber molds are built very differently to accomplish the final part.

We build all the tooling in our tool shop on site for our domestic projects, and we design the tooling specifically for the type of injection process used for both silicone and liquid silicone rubber.

The silicone injection molding process is used with both HCR (gum stock) silicone and also for LSR (liquid silicone rubber). Both of these processes use injection molding technology to increase throughput while minimizing waste. This helps lower per part price.

Silicone prototypes are commonly used to refine the design process (fit/form/function) and it is common for Rubber Industries to make a silicone prototype tool in just a few days including custom silicone parts.

Silicone Injection Molding with our partners in China

We also work with our partners in China to offer:

- silicone injection molding

- rubber injection molding

- rubber injection molding companies

- silicone injection molding temperature

- custom rubber injection molding

- epdm rubber injection molding

- injection molding low quantity

- injection molding machine for rubber

- injection molding rubber

- liquid rubber injection molding silicone free

- low volume silicone injection molding

- pbt injection molding

- rubber injection molding prototypes

- rubber injection molding quote

At Rubber Industries, we are committed to providing custom precision silicone products to make every project that much easier to meet your demanding applications. By combining our extensive resources with over 50 years of experience, we offer the fastest complete silicone services from proto to production. We also provide easy access to high quality items, including the following:

* Dual Durometer

* Seals

* Gaskets

* Bellows

* Custom Medically-Based Items

Whether you need these or other in-demand tools, you can find everything that will make your task more convenient at Rubber Industries.

We start by placing our focus on designing the type of high-quality tools you need to get the job done right every time. By giving you easy access to high-quality gaskets, seals, bellows, and other custom tooling items, we can provide the type of peace of mind you need for each important project. We also pride ourselves on our partnerships with other international-based businesses who create the same high-quality tools we have become known for. Whether you require high volume or low volume production, you will be sure to find the custom tooling consumer tools you need to complete your most important tasks and projects.

Our production team understands that your time is of utmost importance to your business success. We don't want you to wait weeks or months for the vital tools that you need to complete your projects on time.

Every extra minute you wait can mean the loss of important income that your business relies upon for continued success and growth.

This is why we offer the fastest complete silicone services from proto to production. We have created and shipped as many as 10,000 custom molded industrial parts in one week, offering some of the fastest silicone production tooling available. High volume and low volume production needs create no issues for our skilled team of professionals. Industrial parts, medical products, and custom molded items can be designed according to your specifications in the fastest manner possible.

Our qualified team of professionals are equipped to provide for your specific needs no matter what industry you may be involved with. From automotive to medical industries, our overmolded parts will fit your precise needs each and every time. Our extensive experience gives us the upper hand in offering the types of silicone and custom silicone tools required for important projects across all industries. Whether your industry requires automotive items, medical, industrial, and parts like diaphragms, o-rings, or custom colors, no request is too big or too small.

Contact us to get your project started!

We have had extensive experience in the custom silicone tooling and molding industry, and our experience for over 50 years keeps your projects and parts moving to you 24/7/365. Therefore, we understand what it is like to be up against deadlines that create a great deal of stress and pressure. Our number one goal is to make your deadlines easier to meet.

We take pride in offering an array of custom colors, custom silicone to metal bonded items, and silicone injection tools. We want to reduce the stress you experience when facing deadlines that affect your bottom line and reputation.

At Rubber Industries, we are dedicated to providing superior customer service and outstanding high-quality items. We proudly offer the fastest silicone production tooling to make meeting your needs that much easier. If you are looking for the following items for your business, consider the wide array of options available at Rubber Industries:

* Dual durometer

* O-Rings

* Diaphragms

* Overmolded Items

* Silicone injection and Silicone Items

* Custom silicone to metal bonded

At Rubber Industries, we understand the importance of experience, trust, diligence, and excellent customer service. We know that you have many options available to you when it comes to choosing a source for all your customized tooling needs.

We appreciate the opportunity to provide you with continual support, fast delivery, and the highest quality items available. Please contact us further for more information on the services and items we provide to make your life and business easier. If you would like a price quote on a specific project, please contact our customer service number or fill out the online form. We look forward to serving your needs for all your projects, large and small.

* Dual Durometer

* Seals

* Gaskets

* Bellows

* Custom Medically-Based Items

Whether you need these or other in-demand tools, you can find everything that will make your task more convenient at Rubber Industries.

We start by placing our focus on designing the type of high-quality tools you need to get the job done right every time. By giving you easy access to high-quality gaskets, seals, bellows, and other custom tooling items, we can provide the type of peace of mind you need for each important project. We also pride ourselves on our partnerships with other international-based businesses who create the same high-quality tools we have become known for. Whether you require high volume or low volume production, you will be sure to find the custom tooling consumer tools you need to complete your most important tasks and projects.

Our production team understands that your time is of utmost importance to your business success. We don't want you to wait weeks or months for the vital tools that you need to complete your projects on time.

Every extra minute you wait can mean the loss of important income that your business relies upon for continued success and growth.

This is why we offer the fastest complete silicone services from proto to production. We have created and shipped as many as 10,000 custom molded industrial parts in one week, offering some of the fastest silicone production tooling available. High volume and low volume production needs create no issues for our skilled team of professionals. Industrial parts, medical products, and custom molded items can be designed according to your specifications in the fastest manner possible.

Our qualified team of professionals are equipped to provide for your specific needs no matter what industry you may be involved with. From automotive to medical industries, our overmolded parts will fit your precise needs each and every time. Our extensive experience gives us the upper hand in offering the types of silicone and custom silicone tools required for important projects across all industries. Whether your industry requires automotive items, medical, industrial, and parts like diaphragms, o-rings, or custom colors, no request is too big or too small.

Contact us to get your project started!

We have had extensive experience in the custom silicone tooling and molding industry, and our experience for over 50 years keeps your projects and parts moving to you 24/7/365. Therefore, we understand what it is like to be up against deadlines that create a great deal of stress and pressure. Our number one goal is to make your deadlines easier to meet.

We take pride in offering an array of custom colors, custom silicone to metal bonded items, and silicone injection tools. We want to reduce the stress you experience when facing deadlines that affect your bottom line and reputation.

At Rubber Industries, we are dedicated to providing superior customer service and outstanding high-quality items. We proudly offer the fastest silicone production tooling to make meeting your needs that much easier. If you are looking for the following items for your business, consider the wide array of options available at Rubber Industries:

* Dual durometer

* O-Rings

* Diaphragms

* Overmolded Items

* Silicone injection and Silicone Items

* Custom silicone to metal bonded

At Rubber Industries, we understand the importance of experience, trust, diligence, and excellent customer service. We know that you have many options available to you when it comes to choosing a source for all your customized tooling needs.

We appreciate the opportunity to provide you with continual support, fast delivery, and the highest quality items available. Please contact us further for more information on the services and items we provide to make your life and business easier. If you would like a price quote on a specific project, please contact our customer service number or fill out the online form. We look forward to serving your needs for all your projects, large and small.