IMPORTANT UPDATE:

Rubber Industries is designated as an essential manufacturer due to our Medical and Department of Defense manufacturing.

We continue to operate all aspects of our tooling and manufacturing 24x7x365

Custom Rubber Molding and Custom Silicone Molding

Phone: 952-445-1320

- Fifty Years Of Experience: We have been creating the highest quality, custom molded, rubber, silicone and LSR products for almost fifty years. This allows us to create the best products and provide the fastest complete rubber and silicone services from proto to production.

- We manufacture custom molds, custom tooling, rubber overmolded parts, custom silicone and custom silicone to metal bonded parts, and LSR custom tooling and LSR custom molded parts.

- We make 100's of custom tools per year and manufacture tens of millions of parts per year

- Our in-house team of production engineers, mold designers, engineers, chemists, toolmakers, and custom compound mixers all work together to ensure that you receive the highest quality pieces to match your application.

- We can create the perfect custom rubber and silicone custom molded parts for any application that you can think of with our thousands of custom compounds. We produce parts made of polyurethane, butyl, HNBR, flourosilicone, nitrile, natural rubber, Viton, FKM, and countless other compounds.

- Some examples of our custom pieces are seals, gaskets, o-rings, bellows, and diaphragms. We produce these by the millions annually for our wide range of respected customers. If you need custom pieces, we can handle your order. Whether it be high volume production or low volume production.

- We offer the most comprehensive and fastest rubber, LSR, and silicone production tooling services in the industry. Within as little as one to ten days, we can take your project from prototype to high volume production.

- We never close. We offer our comprehensive services twenty four hours a day, seven days a week, three hundred and sixty five days a year. This allows us to the fastest prototype and production speed and provide you with your required tools and parts in record time.

|

|

Rubber Industries, Inc., is the leader in custom molded rubber and silicone products. We have been in the custom molded rubber and silicone industry for over 50 years and can produce any custom molded rubber or custom molded silicone part to meet your needs. If you need custom molded rubber or custom molded silicone products then we have the technology, equipment, presses, and to help you design your product, build a mold, and manufacture the part all in a matter of days, not weeks or months.

Rubber Industries incorporates a number of different types of manufacturing processes depending on the specific product.

The brands you trust daily.... trust us with some of their most critical parts!

Custom Rubber Molded Parts and Tooling

- When you get your custom tooling made by us, we provide an unmatched level of quality. Other services create their prototypes from cheap aluminum with a short lifespan. We only use 4130 steel to create your prototypes. 4130 steel has a long lifespan and provides reliable productivity for the entire duration of its lifespan. By purchasing your prototypes from us, you save yourself money, time, and effort. Don't buy cheap prototypes and have to spend more to replace them. Buy our 4130 steel prototypes and enjoy the reliability of real tools.

- All of our high quality pieces can be made with custom colors to match your project from the start with perfection.

- At Rubber Industries, we continuosly provide our services to the world's biggest industries. We supply the biggest brands in the automotive, industrial, medical, and even consumer industries.

- Companies such as Ford, GM, Emerson, Honeywell, Bell Helicopter, and even the world renown Walt Disney Company all trust Rubber Industries to create and manufacture the most critical silicone pieces, custom silicone to metal bonded pieces, custom molds, and custom silicone tooling that they need.

- With our overmolding service, we can create pieces that are overmolded on materials such as glass filled nylon and many more materials to ensure that the piece is strong enough for any application and the perfect match for your project.

- We frequently produce supplies that are used in situations where accuracy and reliability are key. Our seals, gaskets, diaphragms, o-rings, bellows, and more are used in such critical environments as hospitals and medical supplies. They're trusted in automotive use, industrial equipment, and even in your everyday houshold.

- We have partners in Asia to help us produce satisfactory tools and pieces by the millions every year. On top of that, we have the largest tooling and silicone injection shop in the industry on our five acre, USA based, property. Between our own in-house shop and our Asian partners, we can create massive amounts of product in a dramatically reduced amount of time compared to our competitors.

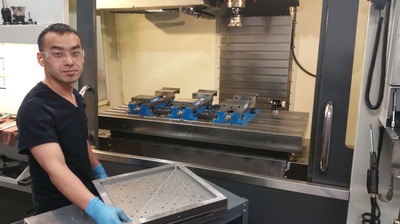

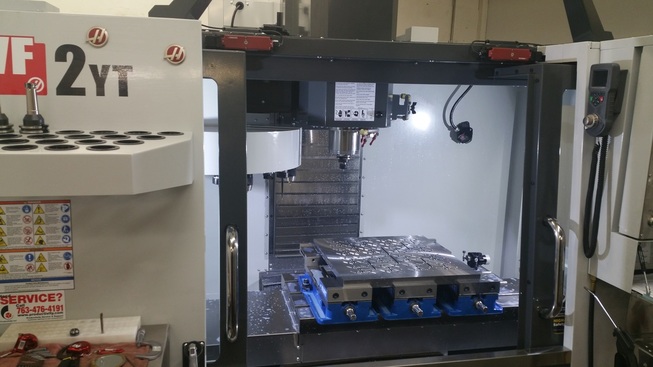

- Our In-House Shop Has A Staggering Amount Of Capability

We are fully outfitted with fifteen pound injection presses, transfer presses, compression presses, molding presses, silicone injection presses, and the most precise LSR presses. We're also home to the industry's largest CNC shop and house more than one hundred CNC cutting machines to create hundreds of custom tools every year. - We Provide The Fastest Complete Silicone Services From Proto To Production

We're the fastest company around when it comes to creating custom molded pieces and custom tooling. We can take your project from the prototyping phase to producing product in high volume in as little as one to ten days.

We're also the only company that can stick with you throughout the entire process. With other companies, you would have to start the prototyping phase with one company and move onto production and manufacturing with another. With Rubber Industries and our vast array of technology and services, you can work exclusively with us from start to finish and build a meaningful business relationship throughout the process. - Not only are we the fastest silicone production tooling company, but we stand out amongst the rest by only using 4130 steel to create our prototypes.

- Our prototypes start at a mere $850 and are guaranteed to provide the most reliable and efficient performance.

- With our steel prototypes, you can begin manufacturing immediately and the tool will last throughout the duration of your project.

- Our molds and tools are also made with precision and strength on mind. Our customers rely on extremely accurate pieces. So, our tools are made with the tightest of tolerances.

- When you buy from us, you can be assured that you only pay for what you purchase. You own the tooling that we create. We don't charge hidden engineering fees or set up fees when you shop with us. The value that we provide through integrity and our quality tools will save you money and time. All while ensuring that your project is completed in a timely fashion and without waiting months for your supplies.

- All of our customers are offered the chance to test the product that they order before committing to purchasing it. This allows you to know exactly how good our custom pieces are and you can trust us as part of a meaningful business relationship.

- We Provide The Ultimate Liquid Injection Molding Service

- Rubber Industries has an extensive list of capabilities for liquid injection molding. We can make both clear pieces and pieces made with custom colors.

- Liquid injection molding and silicone molding are ideal for seals, gaskets, o-rings, and many other items that have to be durable, weather resistant, and elastic.

- Our liquid injection molded items are frequently used in electronics, medical equipment, automotive, and consumer fields. Due to this, we manufacture all of our LSR manufactured pieces in a clean environment to ensure that they are safe for use and sanitary for all applications. It also has a naturally low level of toxicity and will not allow the growth of microbes.

- We also offer our supplies in a dual durometer option. Dual durometer options allow the item being made to have two different hardnesses. This can be crucial to a variety of critical pieces and we provide it through our expert knowledge and skill.

Why Is Rubber Industries The Best Place For All Of Your Molding Needs?

- We are the fastest prototyping, production, and molding company around. We can take your project from the prototyping phase to mass production in a matter of days.

- We have the most comprehensive list of services in the industry. We are the only company that will stick with your project from the very beginning to the very end. We have all of the technology and experience necessary to be your one source for your project.

- While we proudly take on large projects, we also welcome low volume production runs. If you have a small project that needs completed, we will gladly offer our comprehensive services.

- We never close. We remain open every day of the year for twenty four hours a day. So, you can always come to us for a timely, high-quality, and efficient experience.

- We have performed high quality work for fifty years and our family has ran this business for three generations. This has given us the expertise necessary to beat our competition at every turn for our customers.

- Not only do we have five decades of experience, but we're trusted by the brand names that you trust everyday. We make their most critical pieces and have built a reputation on quality and efficiency.

Custom Molded Rubber with our partner in China

We also work with our partner in china to offer:

- custom rubber gaskets

- custom rubber grommets

- custom rubber molding

- custom rubber plugs

- custom rubber seals

- custom rubber bladder

- custom rubber boots

- custom rubber compounding

- custom rubber gaskets

- custom rubber grommets

- custom rubber injection molding

- custom rubber parts

- custom rubber products

- custom rubber sheets

At Rubber Industries, we understand your need to take each important project and make it your own. We have over 50 years of dedicated experience in helping people just like you complete both large and small projects with ease.

Over the last few years, we have invested millions into our extensive US-based production facilities. We also partner with various high-quality production plants across the world. Our combined efforts and extensive experience ensure that you will have constant access to the industrial, automotive, consumer, or medical parts you need the most. We give you access to parts such as:

* Bellows

* Seals and Gaskets

* Diaphragms

* Custom Molded O-Rings

* Quality Dual Durometer Items

While this is not an extensive list, it can give you an idea of the types of products available for your projects. Furthermore, we understand that each project is unique and often comes with its own challenges and deadlines. You should never be stuck waiting for important products you need to complete your job. We provide access to multiple modern injection presses to meet your specific project needs each and every time.

When Speed Matters Most

At Rubber Industries, we have become known for being one of the fastest custom injection molding production companies in the entire industry. We know precisely how valuable your time is to your success. We won't waste any additional time on helping you make your project goals a reality.

We Can Help Within Any Industry

No matter what industry you may be involved with, we can assist you in offering the high-quality products you have come to depend on. For example, we take pride in covering the following areas and industries completely:

* Industrial Components

* High-Grade Medical Equipment

* Automotive Needs

* Consumer Demands

* Defense Contracting

Your Production Volume Needs are Not a Problem

Do you require high volume or low volume production? Do your production needs change frequently depending on your current project? Whether you need high volume or low volume production, you have come to the right place. No project is too big or too small for us to successfully meet your unique needs. The following tools can be yours quickly and easily:

* Seals and Gaskets

* Bellows

* Diaphragms

* Custom-Molded O-Rings

* Overmolded and Dual Durometer Items

Materials and Bonding Process

Over the last few years, we have invested millions into our extensive US-based production facilities. We also partner with various high-quality production plants across the world. Our combined efforts and extensive experience ensure that you will have constant access to the industrial, automotive, consumer, or medical parts you need the most. We give you access to parts such as:

* Bellows

* Seals and Gaskets

* Diaphragms

* Custom Molded O-Rings

* Quality Dual Durometer Items

While this is not an extensive list, it can give you an idea of the types of products available for your projects. Furthermore, we understand that each project is unique and often comes with its own challenges and deadlines. You should never be stuck waiting for important products you need to complete your job. We provide access to multiple modern injection presses to meet your specific project needs each and every time.

When Speed Matters Most

At Rubber Industries, we have become known for being one of the fastest custom injection molding production companies in the entire industry. We know precisely how valuable your time is to your success. We won't waste any additional time on helping you make your project goals a reality.

We Can Help Within Any Industry

No matter what industry you may be involved with, we can assist you in offering the high-quality products you have come to depend on. For example, we take pride in covering the following areas and industries completely:

* Industrial Components

* High-Grade Medical Equipment

* Automotive Needs

* Consumer Demands

* Defense Contracting

Your Production Volume Needs are Not a Problem

Do you require high volume or low volume production? Do your production needs change frequently depending on your current project? Whether you need high volume or low volume production, you have come to the right place. No project is too big or too small for us to successfully meet your unique needs. The following tools can be yours quickly and easily:

* Seals and Gaskets

* Bellows

* Diaphragms

* Custom-Molded O-Rings

* Overmolded and Dual Durometer Items

Materials and Bonding Process

We specialize in meeting all your custom bonding and rubber injection molding needs. This means we work firsthand with a variety of bonding techniques and materials. For example, the following materials and techniques can be used to help you reach your project needs:

* Nitrile

* SBR

* FKM

* HNBR

* Viton

* Rubber to Metal Bonded

* EPDM to Metal Bonded

* Nitrile NBR to Metal Bonded

* NBR to Metal Bonded

* FKM to Metal Bonded

Our high-volume injection molding capabilities can handle your most pressing project demands with ease. Transfer and compression molding with a variety of materials will ensure you always have the right items for each important task you are faced with.

Largest In-House Facilities

At Rubber Industries, we maintain one of the largest in-house production facilities in the industry. We have multiple modern injection presses to meet your specific project needs effortlessly each time. The following benefits result from our expansive in-house facilities:

* Production of Tens of Millions of Items Annually

* Professional Partnerships with Asian Facilities

* Quality Check Procedures to Ensure Low Levels of Defects

* Fast Turnaround Time and Reasonable Shipping Fees from Asia when we source overseas for you

Customization is the Key to Success

The production and management team at our facilities completely relate to the unique needs each project brings to the table. Whether big or small, every project you encounter will be different. We offer highly customizable services, such as:

* Transfer Molding

* Custom Injection Molding

* High Volume Injection Molding

* NBR to Metal Bonded and FKM to Metal Bonded

* Nitrile NBR to Metal Bonded

* Overmolded, Custom Molded, and Custom Tooling Items

* Nitrile

* SBR

* FKM

* HNBR

* Viton

* Rubber to Metal Bonded

* EPDM to Metal Bonded

* Nitrile NBR to Metal Bonded

* NBR to Metal Bonded

* FKM to Metal Bonded

Our high-volume injection molding capabilities can handle your most pressing project demands with ease. Transfer and compression molding with a variety of materials will ensure you always have the right items for each important task you are faced with.

Largest In-House Facilities

At Rubber Industries, we maintain one of the largest in-house production facilities in the industry. We have multiple modern injection presses to meet your specific project needs effortlessly each time. The following benefits result from our expansive in-house facilities:

* Production of Tens of Millions of Items Annually

* Professional Partnerships with Asian Facilities

* Quality Check Procedures to Ensure Low Levels of Defects

* Fast Turnaround Time and Reasonable Shipping Fees from Asia when we source overseas for you

Customization is the Key to Success

The production and management team at our facilities completely relate to the unique needs each project brings to the table. Whether big or small, every project you encounter will be different. We offer highly customizable services, such as:

* Transfer Molding

* Custom Injection Molding

* High Volume Injection Molding

* NBR to Metal Bonded and FKM to Metal Bonded

* Nitrile NBR to Metal Bonded

* Overmolded, Custom Molded, and Custom Tooling Items

No one service is going to meet all your needs. This is why we offer a wide range of items, materials, and bonding procedures to help you address the specifics of each vital project you manage. Transfer molding, large capacity production, and catering to smaller projects create no problems for our production team and facilities.

Exemplary Year-Round Service

We understand that your needs may vary throughout the course of the year. We provide 24-hour service, 365 days a year. We never shut down our manufacturing capabilities so that we can ensure you have constant access to the materials you need the most. You can rely on continual access to:

* HNBR and SBR Items

* EPDM and Butyl Items

* FKM Items

* Custom Tooling and Custom Colors

* Viton and Nitrile Items

* EPDM to Metal Bonded

* Rubber to Metal Bonded

Expertise, Connections, and Speed of Service

With over 50 years of experience serving the precision needs of people just like you, we have learned what it takes to provide outstanding customer service when it matters the most. We offer the fastest production time in the industry, creating completely customized items in just a few days. You will never find yourself waiting weeks or months for the items you require.

Our services include the fastest production time combined with thousands of variations on the classic formulas required most often. These customized formulas can include the following features:

* EPDM

* Butyl

* Custom Colors to Match Your Needs

* Custom Injection Molding

* Transfer Molding

Understanding the Silicone Injection Process

The silicone injection molding process began in the 1960's. The manufacturing process is used to mold and bond various materials so that they can be used in a variety of important functions. Injection molding heats and pressurizes silicone and the other materials used. These innovative manufacturing techniques have become one of the most efficient ways to make custom-created silicone molded items of all types.

Why are we at the forefront of this technology?

* Continuous ownership means we provide the same standards of pricing, quality production, and service that you have grown accustomed to.

* Over 50 years of experience means we remain on top of the cutting-edge practices that go into silicone injection manufacturing.

* Our continual investment in our current manufacturing facilities means we have the manpower needed to help you meet both large and small project goals.

* Millions of happy customers mean that you can have complete peace of mind in choosing to work with us for your project needs.

* Offering the fastest production times in the industry means you will never be left waiting weeks or months for the items you need right away.

* Access to a variety of materials and molding protocols means we can create any specific item you need according to your precise demands.

* High volume injection molding is no issue for our expansive production facilities.

For over five decades, we have helped people just like you make their project goals a reality. We do this not only through complete customization of each item required, but also through speedy and reliable service. We can provide you with a complete estimate from the beginning to the end stages of the project you are facing. Choosing to work with us means there will be no surprises and no hidden fees associated with the completion of your most vital projects.

Contact us today for a custom quote and to find out how easy it is to access high-quality, professional, and customized items to make your next project a breeze.

Exemplary Year-Round Service

We understand that your needs may vary throughout the course of the year. We provide 24-hour service, 365 days a year. We never shut down our manufacturing capabilities so that we can ensure you have constant access to the materials you need the most. You can rely on continual access to:

* HNBR and SBR Items

* EPDM and Butyl Items

* FKM Items

* Custom Tooling and Custom Colors

* Viton and Nitrile Items

* EPDM to Metal Bonded

* Rubber to Metal Bonded

Expertise, Connections, and Speed of Service

With over 50 years of experience serving the precision needs of people just like you, we have learned what it takes to provide outstanding customer service when it matters the most. We offer the fastest production time in the industry, creating completely customized items in just a few days. You will never find yourself waiting weeks or months for the items you require.

Our services include the fastest production time combined with thousands of variations on the classic formulas required most often. These customized formulas can include the following features:

* EPDM

* Butyl

* Custom Colors to Match Your Needs

* Custom Injection Molding

* Transfer Molding

Understanding the Silicone Injection Process

The silicone injection molding process began in the 1960's. The manufacturing process is used to mold and bond various materials so that they can be used in a variety of important functions. Injection molding heats and pressurizes silicone and the other materials used. These innovative manufacturing techniques have become one of the most efficient ways to make custom-created silicone molded items of all types.

Why are we at the forefront of this technology?

* Continuous ownership means we provide the same standards of pricing, quality production, and service that you have grown accustomed to.

* Over 50 years of experience means we remain on top of the cutting-edge practices that go into silicone injection manufacturing.

* Our continual investment in our current manufacturing facilities means we have the manpower needed to help you meet both large and small project goals.

* Millions of happy customers mean that you can have complete peace of mind in choosing to work with us for your project needs.

* Offering the fastest production times in the industry means you will never be left waiting weeks or months for the items you need right away.

* Access to a variety of materials and molding protocols means we can create any specific item you need according to your precise demands.

* High volume injection molding is no issue for our expansive production facilities.

For over five decades, we have helped people just like you make their project goals a reality. We do this not only through complete customization of each item required, but also through speedy and reliable service. We can provide you with a complete estimate from the beginning to the end stages of the project you are facing. Choosing to work with us means there will be no surprises and no hidden fees associated with the completion of your most vital projects.

Contact us today for a custom quote and to find out how easy it is to access high-quality, professional, and customized items to make your next project a breeze.